Incubator

An incubator is a hermetic chamber specifically designed for cell culture growth and virus production. BECARV designs and constructs incubators essentially for large-scale cell culture-based manufacturing.

Key features

- Temperature control and homogeneity

- Humidity control and homogeneity

- Monitoring and alarms

Incubators for cell culture-based bio-manufacturing

Incubators are essential equipment for the growth & expansion of cell lines and virus production, as used in the vaccine industry. Temperature should be monitored and controlled very precisely; it should be homogeneously distributed within the incubation chamber. Humidity control is also a key factor to prevent evaporation of culture media.

BECARV mostly designs and constructs incubator units for industrial production of cell culture-based products. BECARV incubators contain an air treatment unit with ‘High-Efficiency Particulate Air’ (HEPA) filter, a ventilator, and an air heating unit to guarantee proper incubation conditions as required for bio-manufacturing in current Good Manufacturing Practices (cGMP).

Applications for incubator

- Large-scale cell-based product manufacturing

- Viral vaccine production with adherent or suspension cell culture

- Recombinant proteins production from cell culture

Customized incubators meeting your needs

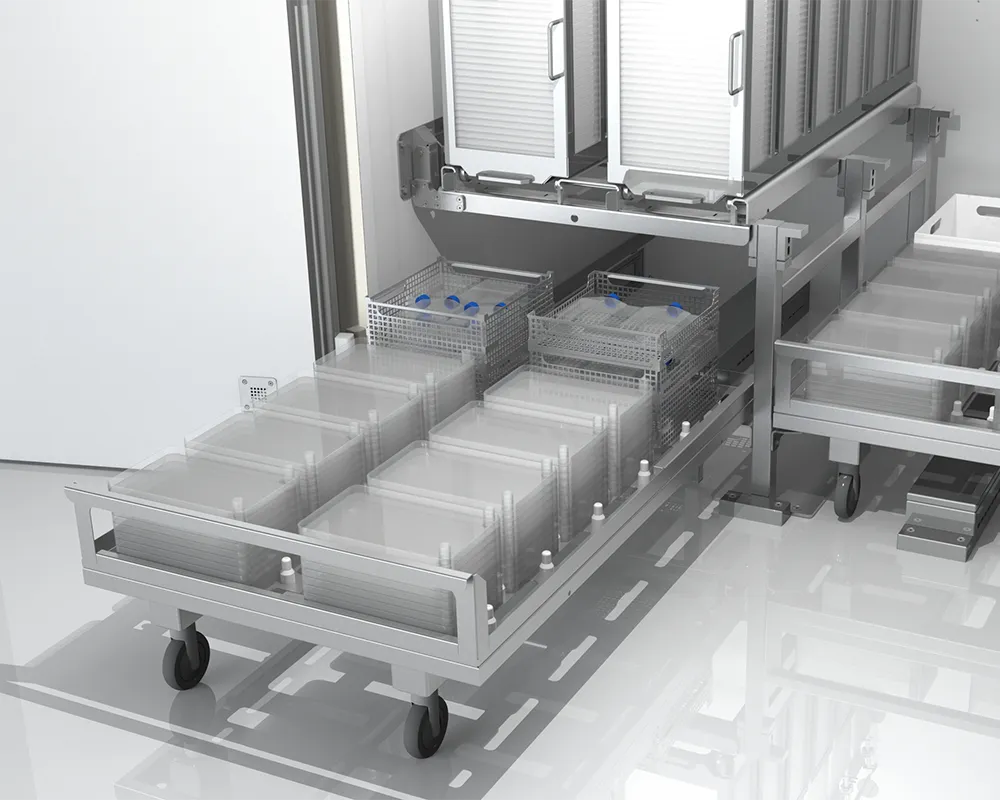

BECARV is known for its expertise and capabilities to customize equipment for the bio-pharmaceutical industry to meet process requirements and client expectations. BECARV designs and delivers incubator units of very large size that are suited to include cell culture devices such as multi-trays, roller bottles or wave-bags on trolleys or on fixed layers for incubation.

BECARV incubators provide a robust control technology guaranteeing a homogeneous and precise temperature & humidity distribution all over the incubation chamber. The incubators are also equipped with additional features such as automated culture systems, remote monitoring and data logging, and alarm systems.

The flexibility in construction of BECARV incubators, their customization and ergonomic design, and their robust control and monitoring systems make them an excellent investment for large-scale cell culture-derived product manufacturing.

Why choose BECARV incubators?

Reliability

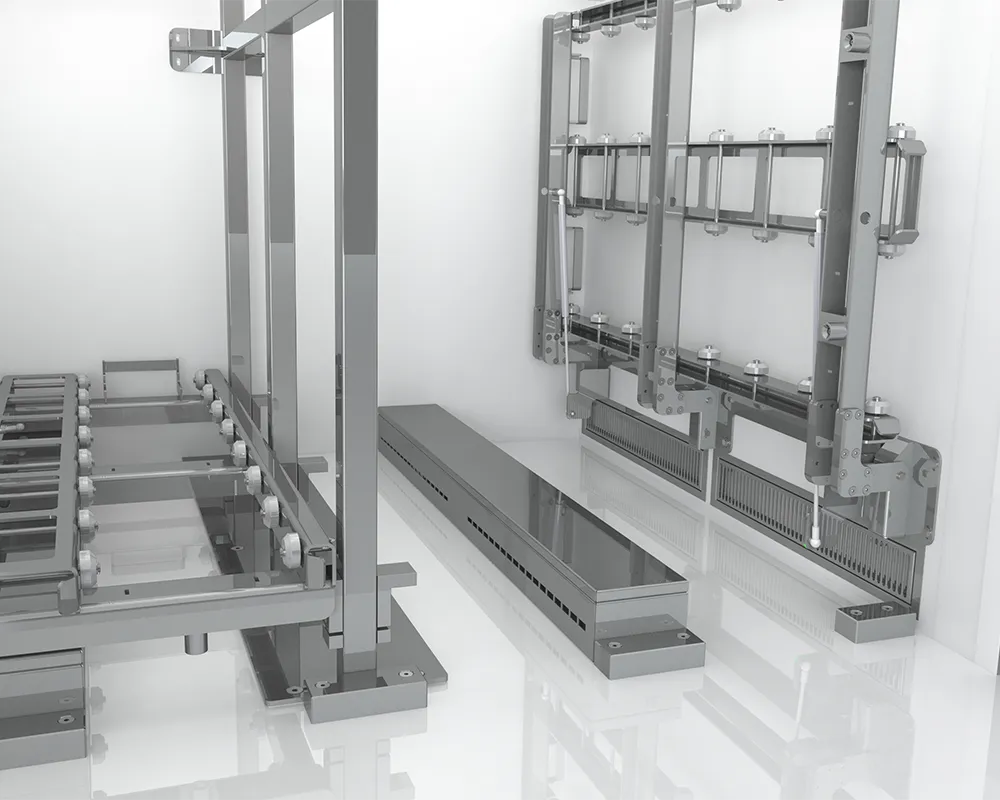

BECARV conceives and constructs incubators with robust materials such as stainless steel and state-of-the art control technology, including an air treatment unit with ‘High-Efficiency Particulate Air’ (HEPA) filter, a ventilator and an air heating unit, to ensure the homogeneity and precise distribution of temperature & humidity within the chamber.

Modular design

BECARV delivers incubator units that are suited for large-scale cell and virus culture using multi-trays, roller bottles or wave-bag system. The largest incubators are conceived as ‘walk-in’ units where the cell culture devices are introduced and kept on trolleys during the cell and virus culture phases.

Expertise

BECARV incubator units are today used in large-scale cell and virus culture for manufacturing of registered products, in compliance with cGMP.

BECARV management approach

BECARV has developed a comprehensive approach to design and construct incubators with and for its clients. The process starts by understanding the process requirements and the client’s expectations. The approved project brief is used by BECARV’s design office to deliver the equipment file and manufacturing plan.

After client approval, the construction is initiated. The first Quality Controls and equipment testing are performed by BECARV prior to delivery, and are followed by installation at client designated site by BECARV’s trained team. Qualification of the incubator is conducted based on Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) protocols to ensure the incubator is correctly installed to meet all quality standards and regulatory requirements.

Frequently asked questions about incubators

What are the differences between an incubator and a thermostatic chamber?

An incubator is conceived with a narrower range of temperatures – in most cases 25°C up to 37°C – as they are usually intended for biological productions with cell and virus cultures in upstream process steps. Thermostatic chambers are designed with a wider range of temperatures & humidity capabilities as they are rather dedicated to multiple industrial and research laboratory applications.

What are the specificities of BECARV incubators?

BECARV incubator units are made of two distinct parts: on the one hand, the technical module that includes the air treatment unit with HEPA filter, the ventilator and the air heating unit, and, on the other hand, the incubation chamber that is air-tight constructed ensuring a precise and homogeneous distribution of temperature and humidity for proper bio-manufacturing operations.