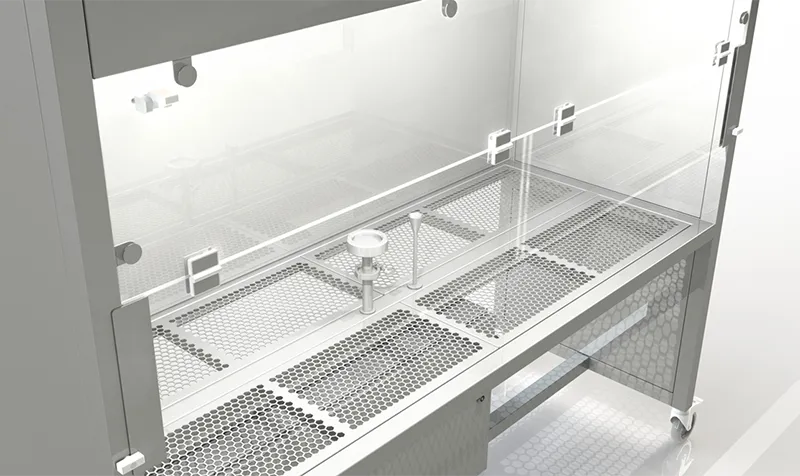

Laminar air flow hood

Laminar air flow hoods, also called laminar flow cabinets or clean benches, are a critical equipment for the bio-pharmaceutical industry and for research laboratories. They provide a sterile environment that protects both the product and the operator from contamination risks during open and manual operations.

Key features

- Sterile environment

- Controlled risk of contamination

- Product and operator protection

Laminar air flow hoods to ensure sterile work environment

A laminar air flow hood operates on the principle of creating a unidirectional airflow that minimizes turbulence and prevents the ingress of airborne contaminants into the working space.

Cabinets are equipped with ‘High-Efficiency Particulate Air’ (HEPA) filters that capture airborne particles, especially living micro-organisms, ensuring the air in the work area is free from contaminants. Laminar air flow hoods serve essentially to protect open and/or manual operations in research laboratories and bio-pharmaceutical productions, guaranteeing the quality & safety of operations.

Applications for laminar air flow hood

Bio-pharmaceutical industry

Laminar air flow cabinets are essential in research activities and bio-product manufacturing involving cell culture or microbiological operations to control the contamination risk of the biological material by extraneous agents. They are also used for Quality Control testing to guarantee reliable results.

Laminar air flow hoods also provide a contaminant-free environment for filling vials, syringes, and other containers with sterile pharmaceutical products. They are used for filtration and filling of cell culture media and additives. Other operations performed under laminar air flow hoods include formulation development, molecular biology research, PCR-based analyses, for example.

Healthcare activities

Laminar air flow ceilings are critical in hospital operating rooms to maintain a sterile field around surgical site and to protect the patient from airborne contamination. Intensive Care Units (ICU) also use laminar air flow ceiling to protect immuno-compromised patients from airborne infections. Pharmaceutical cleanrooms are equipped with laminar air flow hood when producing sterile medications or for drug product filling.

Customized laminar air flow hood to meet your needs

BECARV is recognized by the bio-pharmaceutical industry for its expertise and capabilities to customize equipment, including laminar air flow hoods, meeting the client’s requirements for enhanced quality and safety of bio-manufacturing operations and research activities.

The main features of BECARV laminar air flow hood are summarized below

- High-Efficiency Particulate Air (HEPA) filtration

- Unidirectional air flow to sweep away particle entry

- Grade ‘A’ equipment in grade ‘B’ cleanroom

- Contribution to low bio-burden control

- Environment meeting ISO 5 standards

- Optional equipment addition (particles counter and sampler)

Why choose BECARV laminar air flow hoods?

Reliability

BECARV offers robust and reliable laminar air flow hoods complying with cGMP operations. Such laminar air flow hoods are used at present by several clients for bio-pharmaceutical production and R&D activities.

Safe environment

BECARV studies the characteristics of client operations to design and construct laminar air flow hoods that provide adequate air recirculation and appropriate HEPA filters to optimize the safety of the working environment for the reliability of operations.

Customization

BECARV’s expertise is centred on the design and construction of customized laminar air flow cabinets that meet process requirements and client expectations for enhanced product quality and safety.

Ergonomic design

BECARV analyses and designs its laminar air flow cabinets to provide comfort and accessibility to the user, featuring adjustable height settings and visibility into the workspace (optimized ergonomics).

BECARV management approach

BECARV has developed a comprehensive approach to design and construct laminar air flow hood to the satisfaction of its clients. BECARV analyses the issues encountered by the client to provide a customized technical solution that fits process requirements and client expectations.

BECARV constructs tailored equipment based on an agreed project file and performs the first Quality Control tests prior to delivery and installation at the client designated site. The qualification of the laminar air flow hood is conducted based on Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) protocols to ensure the equipment meets all standards and requirements.

Frequently asked questions about laminar air flow hood

Would BECARV laminar air flow hoods be compatible with cGMP manufacturing?

BECARV constructs its laminar flow hoods in stainless steel and glass materials according to the highest manufacturing standards. Its current clients use their laminar air flow hoods in cGMP bio-manufacturing.

Would BECARV be capable of handling specific design to meet its customer expectations?

BECARV discusses specific requirements with its client prior to designing and adapting the characteristics of its customized laminar air flow hood to meet the process specificities.

Does BECARV offer fully integrated solutions with its laminar air flow hoods?

BECARV is used to designing customized solutions that integrate with other pre-existing process equipment required by the production. The company may also manufacture laminar air flow hoods that include other cleanroom technologies.